March 6, 2020

The HD Platform is an increasingly wider range of high-speed, highly configurable digital sensors play critical – and unique -roles in helping operators to log data much more efficiently. In addition to its range of Standard and Array Production logging tools, Probe has been focusing on cased-hole formation evaluation solutions:

- The ProMAC™ Multi-arm Caliper Tool, which makes it possible to identify integrity problems, such as mineral deposition, corrosion, wear or mechanical deformation, inside a completion.

- The RADii™ Segmented Bond Tool, which measures and maps the quality of cement behind casing in oil and gas wells.

- The RAS™ Reservoir Analysis Sonde, a three-detector pulsed-neutron logging tool for measuring reservoir saturation using Sigma and Carbon-Oxygen techniques.

- The Spectral Gamma-ray Tool, an evaluation tool that offers insight into the radioactivity and mineral composition of cased-hole formations.

More data gathered per well intervention

“For years, the demand for logging tools that are highly configurable and capable of gathering high quality data more efficiently has continued to rise unabated, so we believe that continuing to expand our truly intelligent, effective formation evaluation solutions is critical to our customers’ success,” said Martin Barratt, VP Global Sales of Probe.

“The HD Platform is the result of a concerted initiative to enhance our field-proven tools with the highest quality measurements in the industry. By enabling fully combinable configurations, we are confident that Probe delivers on every front. By employing HD Platform compatible logging tools, service providers can now acquire more data per run in every well intervention. This enables operators to meet key objectives with a minimal number of well entries, improving efficiency and reducing cost.”

The HD Platform: what it is and how it gathers data more efficiently

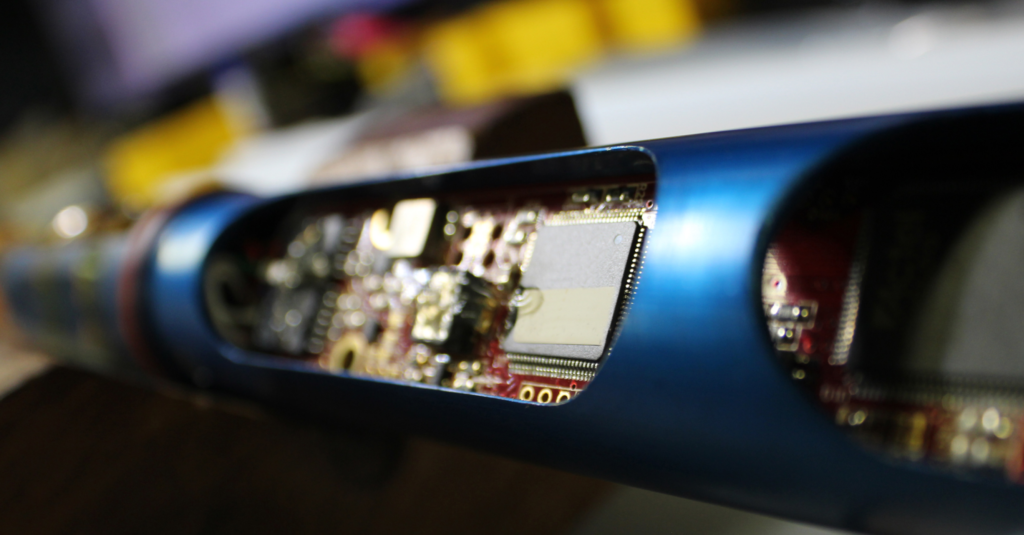

The new HD Platform consists of two parts: an inter-tool communications bus and mono-conductor telemetry which is managed by the Telemetry Control Unit (TCU). The inter-tool communications bus is a single wire bi-directional system that operates at 500kpbs, which is ample speed to accommodate many different combinations of logging tools. The controlling telemetry – or alternative memory tool – samples sensors at a rate of 50 times per second, allowing high data rate tools and, for example, multi-arm calipers to provide high vertical resolution. Commands and instructions are also sent to the sensors on the same single wire bus.

The TCU handles all communications to surface. This device controls the data collected by the tools below, and packages it for transmission to the surface system. It receives commands from the surface system via the fast downlink, and responds back to the surface, as necessary.

The TCU can be replaced by the Memory Logging Tool (MLT) allowing all HD sensors to be deployed on slickline and coil tubing, among others. The HD Platform is a modular design offering simple mechanical maintenance and supported by plug0in electronic boards. It is well suited to both conventional and remote environment operations. Looking ahead, as part of its continuing commitment to developing technologies that gather comprehensive data, Probe plans to integrate HD telemetry technology into all current and future cased-hole logging tools.